There’s no denying the romantic appeal of the cascading bubbles and tight foamy head of a properly poured nitro beer, but first the facts. Nitrogen is largely insoluble in beer (80–90 percent less so than carbon dioxide) at the temperatures and pressures we use to serve beer. Nitrogen is also flavorless, lacking the lemony acidic carbonic bite of carbon dioxide gas. And nitrogen’s use in beer gas is primarily to create higher pressure to force beer through a stout faucet. With that in mind, is there another way to accomplish the end result—that beautifully poured pint—without the nitrogen gas?

Before we explore how to capture that “nitro halo” in a glass, we need to look at the origin and function of nitrogen and the stout faucet.

Traditional hand-drawn cask ales always suffered from oxidation and short shelf life because air entered the cask to replace the beer as the beer was drawn. As carbon dioxide became more readily available, the problem was solved by replacing air with carbon dioxide gas. However, to serve from a keg that was 20 feet or farther away from the faucet, the pressure in the keg was such that carbonation levels rose significantly, from about 1.5 psi to 2.4 psi and higher. For some beer styles (stouts, in particular), the customers were less than overwhelmed by the resulting carbonation and taste.

In the 1950s, Guinness pioneered the use of nitrogen as an inert “pusher” gas, allowing their beer to maintain the classic low carbonation levels and yet still be pushed through the long draft line to the faucet. However the near-flat beer looked lifeless in the glass. Enter the stout faucet: its design includes a small disc with five tiny holes—a “restrictor plate” that forces what nitrogen and carbon dioxide is in solution to nucleate and foam—followed by a “straightener” to control the near violent spray. This “nitrogenated” beer became the new and true way to serve a proper stout because the nitrogen kept the pressure high, the carbon dioxide levels low, and the beer smooth.

So it would seem there are three things happening: low-carbonated beer being pushed with an inert gas through a restrictor plate to produce foam, beer becoming increasingly flat as the keg empties, and relatively flat beer being exalted as near other-worldly delicious. All of this happens with a more expensive gas blend held in a more expensive tank and run through a more expensive regulator—all to replicate historic gravity-poured beers.

But wait! Let’s look at how we might duplicate the result without spending the extra money on a special tank, regulator, and faucet. If it’s true that nitrogen is flavorless, virtually insoluble, and useful only to push beer, can’t we simply carbonate to a suitably low level and push harder with the carbon dioxide gas we already have at our disposal? To see what I mean, try the old syringe trick: pour a pint of fairly low-carbonated beer, pull about a half ounce into a plastic syringe, and squirt that half ounce quickly back into the glass. You will be amazed at how nitro-like the effect is.

The answer, of course, is yes—you can make a nitro-like setup with basic draft equipment. All you need to do is find the right holding pressure for the carbon dioxide portion of the beer gas, ramp up the serving pressure for the pour, and then de-gas to return your keg’s headspace pressure to maintenance level (to avoid over-carbonating the beer). You can then get suitable results using a standard faucet, but if you have a nitro faucet, that’s all the better.

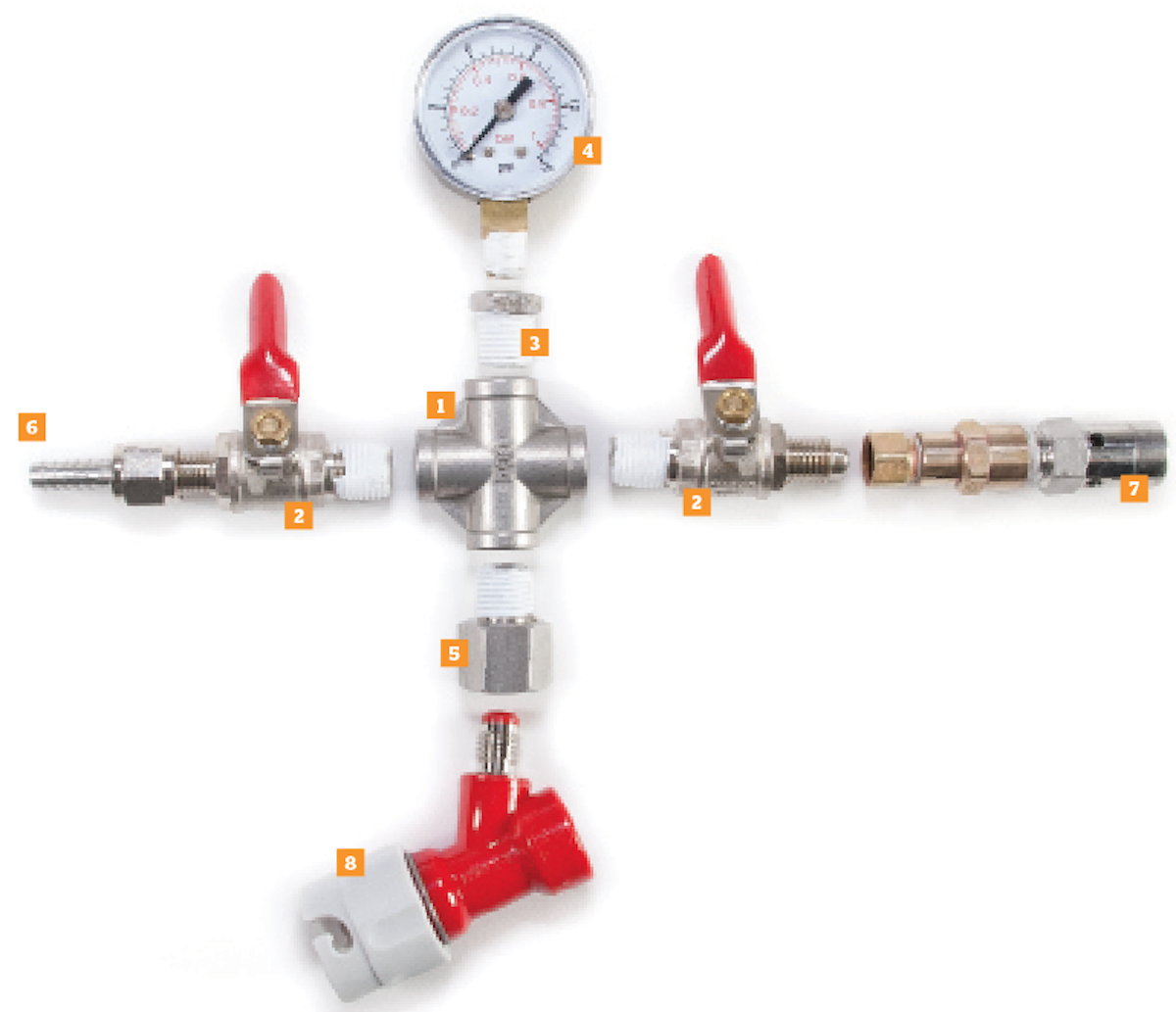

While this sounds simple, in practice it can be quite a bit of work—the process of bleeding pressure off a keg can involve a level of fiddling that most may not wish to endure regularly. Our solution is a device that couples a spunding valve and gauge with “in” and “out” shutoffs, which—when properly set—will bleed the excess pressure from the keg after serving in a measurable and precise way.

Let’s assume that you have multiple kegs being served from the same carbon dioxide tank. You want to be able to overcharge only one keg and leave the others at the standard pressure and return the overcharged keg to its lower pressure, which seems to be about 6–8 psi. Your favorite homebrew supply shop should be able to provide all of the fittings that you need:

- One ¼" MPT cross

- Two shutoff/check valves

- One 1/8" FPT x ¼" MPT adapter

- One mini pressure gauge

- One ¼" MPT x ¼" FFL adapter

- One FFL swivel nut and barb

- One spunding valve

- One soda keg disconnect

- Teflon tape

Follow these step-by-step directions to assembling the inline pressure-bleeding device:

- Put the shutoff/check valves in two ports of the ¼" MPT cross (which ports isn’t important). Don’t forget to put the Teflon tape on all MPT fittings to avoid leaks.

- Using the 1/8" FPT x ¼" MPT adapter, put the mini pressure gauge in a third port on the cross.

- Put the ¼" MPT x ¼" FFL adapter in the fourth port of the cross.

- On one of the shutoffs, put the FFL swivel nut and barb going to the regulator manifold.

- Attach the spunding valve to the second shutoff; this will be set to the static storing pressure using the mini gauge.

- Thread the soda keg disconnect onto the ¼" MPT x ¼" FFL adapter on the fourth port.

To use your new “nitraux” device (faux nitro… get it?), simply set your regulator to the storage pressure, open both shutoffs and slowly open the spunding valve until it starts to bleed, then back it up a quarter of a turn. Check the mini gauge against the regulator gauge just to be sure they match. If you increase the regulator pressure now, it should simply bleed out of the spunding valve. You may want to mark this spot on the spunding valve for future use (or simply tape it into place).

Now, shut the spunding valve, turn the regulator up to 30 psi, serve a lovely pint (or several) of pub-style ale, and enjoy. When you’re finished serving, simply set the regulator back to match your other kegs on tap and then shut off the “in” valve and open the spunding side, to drop the keg’s pressure to 6–8 psi storing pressure.

Our initial tests with this process have proven positive, but one thing we learned early was that when using a nitro faucet it’s imperative that the beer be well-fined, or the restrictor plate quickly gets clogged. Also, the dialing in is a bit tricky. The sweet spot for carbonation seems to be in the 1.5–1.8 vols of CO2 range, which needs about 3–6 psi at 40°F (4°C). We have also seen dramatically similar results using a standard faucet—no restrictor, no straightener.

A final important question remains: How much can I get for my used nitro setup?