SPONSORED CONTENT

High-speed, high-volume packaging lines—more than 1,000 containers per minute (CPM) make an easy case for automation in depalletizing. You simply can’t run the line without it.

But what about the other end of the spectrum? What about emerging beverage innovators, pilot copacking lines, and small to mid-sized in-house packaging operations running 30 to 100 CPM? These operations typically have one or two operators receiving empty containers and hand-loading them on to a rotary table or conveyor. Is there a business case to automate even at these lower speeds?

The simple and emphatic answer is YES!

Ska Fabricating has spent decades supplying and serving customers on both ends of the volume spectrum. We pride ourselves in having a solution for every budget and need. And we’ve heard all the initial reactions from lower volume packaging houses—“We are too small for automation,” or, ”Automation is too expensive for us,” or, ”We’re not automation experts and don’t know where to start.”

Here are four easy steps to evaluate and implement an automated depalletizing solution, so that business owners can enjoy increased profits on the very first day of operation and achieve total cash payback in well under 12 months.

Step 1: Do the Math

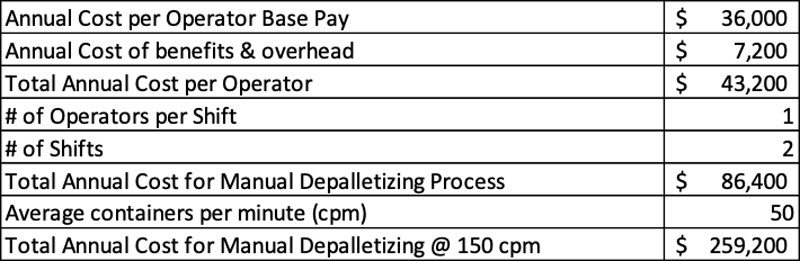

Below are high-level estimates Ska Fabricating has used with lower-volume packaging operations to analyze Return on Investment (ROI) modeling for automated depalletizer equipment investments.

Capture your high-level labor costs as follows:

Then, capture the investments costs of Automated Depalletizing Equipment for lower-speed lines (include a range of options to help you fine-tune the perfect match):

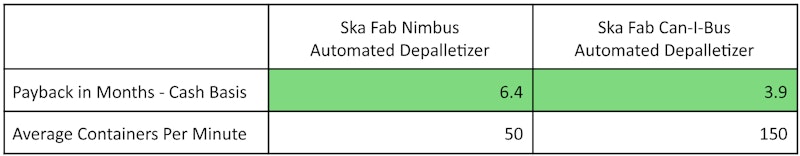

For a simple cash flow “payback” period, divide the (Cost of Equipment) by the (Annual Cost Savings from removing the Manual Depalletizing Operation) * 12 months per year. You can see:

That means you can recover your total investment from labor savings alone in only about six months! And you can do it even faster at higher volumes.

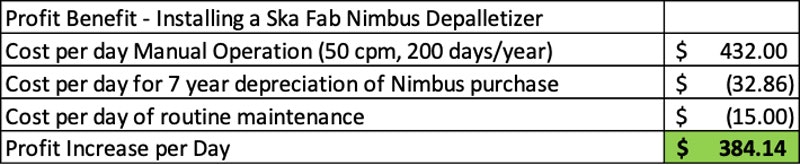

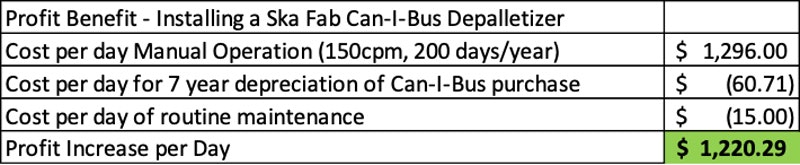

To understand how this investment positively impacts your profits each day, simply take the daily cost of your current operation, and subtract the daily depreciation rate on the purchased equipment plus the daily maintenance costs to keep the equipment running. You can see:

The profit improvement is immediate and large. You can start saving almost $400 per day at lower volumes, and over $1,000 per day for higher volumes—on the very first day of operation.

While these financial numbers are an immediate call for action, make sure to take the next steps to fully document all the benefits and complete a thorough supplier selection, so you get the full benefits your packaging operation deserves.

Step 2: Consider the Other Benefits to Make Your Case

Cans loaded into a Microbus.

People Availability: Unemployment in the U.S. manufacturing sector continues at levels below 3 percent. This creates constant pressure and challenges to hire people for these roles. Freeing up even just two people in a small packaging operation can greatly increase productivity and leverage that talent elsewhere.

People Retention: The U.S. Department of Labor shows manufacturing turnover at 40 percent. So even if you can recruit people, will you be able to retain them for any length of time? While a component of retention is wages, people want to work in jobs with meaning, with purpose, with great teams, and have an opportunity to grow. Ska Fabricating’s experience is that automating aspects of the depalletizing processes takes away some of your lowest-level repetitive positions, and gives those employees a chance to grow, improving retention and allowing you to keep high-performing and high-contributing team members.

Hygiene: Container manufacturers go to great lengths to ship clean containers with tier sheets protecting containers from debris and contaminants. Having operators leaning over open containers and touching each container to load them creates much higher risks of contaminating the container—even with protective gloves and hair covers.

Safe Working Environment: Constant repetitive motion can create safety and wellness issues for your team. The Manufacturing National Safety Council and OSHA have documented that more than 6 percent of operator injuries come from repetitive-motion operations. Automated depalletizer equipment removes the entire manual repetitive-motion process from your operation.

Scaling for growth: While you get immediate cost savings and profit benefits on your first day, if you install equipment for future growth, you are better prepared to scale and seize new top-line revenue opportunities much more quickly, and with higher quality, than by bringing on even more manual labor. The financial analysis above shows that both a 50-CPM and a 150-CPM solution offer great payback and profit improvements.

Step 3: Choose the Right Equipment Partner

The financial benefits are amazing, and so are the other qualitative benefits. Now—time to find the right partner.

Many depalletizing equipment companies have made a conscious decision to only focus on the highest-volume operators. They have turned their backs on the innovators, the start-ups, the pilot lines.

There are other niche depalletizing-equipment suppliers who only do manual and semi-automatic depalletizing equipment, but they haven’t invested in any capabilities greater. While they may serve your needs today, will they be able to scale and serve your needs tomorrow?

Choose a company as a partner who can help you automate and increase profits today, and be there for you as volumes and production rates grow in the years ahead. Definitely consider Ska Fabricating in your selection process. We have very deliberately set a strategy to have a solution available for every budget and scale—whether you are running 30 to 50 CPM or 1,000-plus.

The Can-I-Bus Depalletizer is a beverage industry staple. Able to handle both full- and half-height pallets, this machine’s small footprint makes it ideal for many facilities. Capable of depalletizing cans at speeds up to 400 CPM, the Can-I-Bus is easily paired with our S-Grip Lowerator, which seamlessly brings cans to a filler while cleaning them, and also allows for tool-less changeovers between can sizes.

The Nimbus Depalletizer is a semi-automatic, half-height machine designed for speeds up to 50 CPM. It has an automated pallet lift with adjustable photo eye and an automatic belt-driven sweep. It is a fully portable machine that is able to be moved and stored (including the rotary table) when not in use with a pallet jack.

Our most compact depalletizer is the Microbus. This machine is capable of speeds up to 30 CPM, and is semi-automatic. The pallet is lifted by manual crank operated by hand or with a drill. Once the operator manually lifts the pallet carriage, the sweep pushes the cans to the rotary table and continues to advance the cans as needed. Built for half-height pallets, the Microbus’ rotary table and the automated sweep can be folded away and stored when the depalletizer is not in use.

Step 4: GO!

Regardless of which supplier you pick, the case for moving forward is incredibly strong. Very few automation opportunities you will find in your career will have this remarkable level of quick payback and improved profits.

“Ska Fabricating has had a long history supporting the craft beer industry,” says Steve Sherman, CEO of Ska Fabricating. “We won’t be successful if our customers’ canning operations aren’t successful. As this market matures, we are constantly looking for ways to lower their costs, improve their productivity, and improve their bottom-line profits. It’s what we do.”

The quicker you get started, the quicker you will enjoy higher profits and higher employee engagement and retention. It’s time to move. Now.

SPONSORED CONTENT