Cryo pellets are made of concentrated lupulin from whole-leaf hops. Resins and aromatic oils are preserved using a proprietary and patented cryogenic separation process in a nitrogen-rich environment. The delicate lupulin is gently removed from the bract, or leaf matter, with a single screen passing through a mechanical sieve. The concentrated lupulin is then pressed through our liquid nitrogen–cooled pelleting die for a user-friendly pellet shape. They are immediately sealed into their oxygen-impermeable pouches, packaged, and shipped.

What happens to them next is up to you.

When asked if anything has changed about our Cryo process since its inception, Yakima Chief Hops director of research and development Patrick Jensen says, “Cryo hasn’t changed; the world has.”

Modern brewers constantly strive to achieve greatness with efficiency, and drinking some of the success stories can be inspiring. Using Cryo Hops pellets instead of traditional T-90s offers the brewer higher oil concentrations in a smaller footprint, reducing shipping volumes and cooler storage. The benefit of less hop matter can translate to more finished beer—fewer pellets leave less trub soaking up wort in your kettle, whirlpool, or precious beer in your fermentors. This reduction in absorption allows you to increase revenue by producing more beer each year, or by producing the same amount in fewer batches. For every barrel of beer gained, the brewer uses water, malt, utilities, and labor more efficiently.

Wander Brewing, located in Bellingham, Washington, swapped a fraction of the hop bill for one of its core IPAs to Cryo. “After transitioning Shoe Toss to a blend of T-90s and Cryo pellets, we were able to shrink the total amount of hops per batch by 25 percent while also seeing an increase in total per-batch yield of about 6 percent,” says Lou Waldmeir, Wander’s head brewer.

He notes that the recipe change hasn’t impacted customers’ perception of the old-school West Coast IPA, a critical consideration when updating a flagship brand. “We tried a few different variations of the beer with different blends of Cryo and T-90s before settling on a blend. The YCH survivable hop-oil chart was helpful in trying to predict this. We ended up really liking how Cascade’s flavor and aroma expressed itself in the more concentrated form.”

Unsure how to get started with Cryo? Input your brewhouse values into this handy calculator to see how Cryo Hops can impact your brewery’s efficiency.

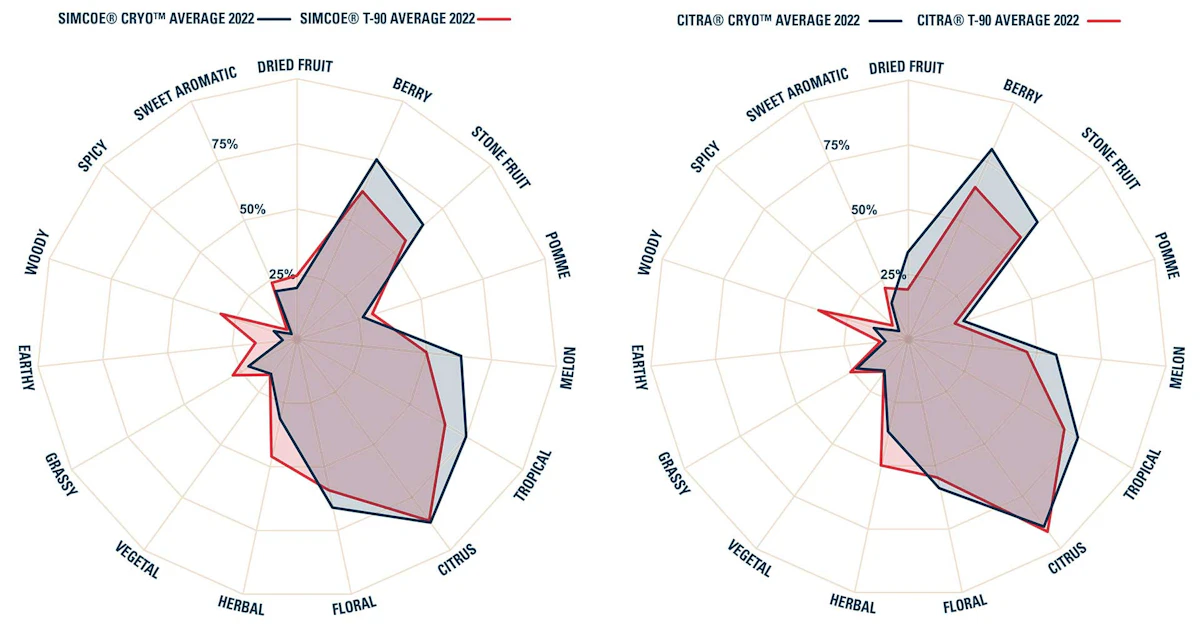

Cryo pellets can be used anywhere in the process that you would use traditional pellets or whole-leaf hops. When integrating them into your recipes, we suggest starting at 40 to 50 percent of the standard T-90 weight. The exact percentage can vary, but this is a great starting point. Cryo Hops beers showcase pronounced zest with reduced grassy and vegetative characteristics. Some brewers prefer to keep the hop bill a mix of Cryo and T-90 to represent a whole mix of hop flavors, accentuating the resinous and juicy attributes that shine through with Cryo.

“A brewer is an artist, and Yakima Chief Hops provides a broad palette of flavors,” says Tessa Schilaty, sensory and brewing research manager at Yakima Chief Hops. “We offer some hop varieties in both T-90 and Cryo versions, providing a more diverse range of shades or hues to work with. It's an expanded color spectrum for the creation of beer.” By exploring these differing flavors and aromas throughout the brewing process, the brewer is empowered to craft a finished product with captivating sensory attributes.

“I would say, definitely use it,” says Robin Schumacher, co-owner and brewer at Stoup Brewing in Seattle. Stoup was one of Cryo Hops’ earliest adopters, experimenting with the trial powder product before it realized its current pellet form. “Getting that purity in hop-oil qualities, the aroma, and flavors that you don’t necessarily get with the T-90s—it’s just a really excellent addition to a beer.”

Sensory assessment of 2022 Simcoe® Cryo and Citra® Cryo samples shows increased perception of berry, stone fruit, and tropical characteristics, along with reductions in woody and herbal notes compared to their T-90 counterparts. Sensory characteristics are determined by calculating the percentage of assessors who reported the presence of each aroma on a Check-All-That-Apply (CATA) ballot.

“We found the advantage of using Cryo is that less is more,” says Brad Bensen, co-owner and head brewer at Stoup. “When you really look at using half as much of it and getting increased efficiencies, ultimately more beer in package, less waste going into your waste drain, it’s really a no-brainer.” Cryo Hops offer increased efficiency not just for your brewery but across the whole supply chain through reductions in freight and storage. Utilizing Cryo can deliver measured improvements in finished beer yields with a positive impact on your bottom line.

Join the award-winning team at Stoup in their brewhouse for more tips and advice when using Cryo Hops!

Embedded content: https://www.youtube.com/watch?v=D-24IgJmeR8

Cryo pellets also have proven effective at mitigating the effects of hop creep—that is, the occurrence of refermentation after a hop addition. Hop creep can be a pest to brewers, distorting the targets for alcohol, diacetyl, and CO2 in the final product. Trials comparing whole hop, bract only, and lupulin factions of hop matter have confirmed that the lion’s share of diastatic enzymes responsible for hop creep reside in the bract. The process of creating Cryo Hops divides the hop into two parts: the concentrated lupulin to be pressed into Cryo pellets, and the bract, which is repurposed downstream. (For more comprehensive information on how Cryo Hops effectively counter hop creep, this document summarizes the studies and references.)

When Yakima Chief Hops launched Cryo Hops in 2017, it was considered the biggest discovery in advanced hop processing that the industry had seen in decades. Cryo Hops are not merely glorified T-45 pellets. Receiving a U.S. patent means that our process is a significant and measurable improvement from any other hop production process and is exclusive to Yakima Chief Hops. “All of our products are made to be the highest quality,” says Jensen, the R&D director, “and our innovative products are made to improve the sustainability of the hop supply chain.”

- Cryo Hops commonly hold higher concentrations of oils and alpha acids than any other concentrated lupulin pellets, meaning greater efficiency in the brewing process.

- Cryo pellets are gently milled and only take one trip through a mechanical sieve to separate the delicate lupulin from the bract.

- Our Cryo pellets undergo the coldest pelleting process in comparison to any other pellet on the market.

- We have the lowest O2 levels throughout the entire process.

- Minimal handling compared to other lupulin-rich processing.

- Prior crop year Cryo pellets are guaranteed fresh and punchy for three years from the packaging date (potentially longer).

- Research indicates that the use of Cryo Hops can mitigate the effects of hop creep.

With an industry landscape characterized by rising expenses and heightened consumer consciousness, integrating Cryo Hops could be a game-changing tool for your brewery. Experience the transformative impact of Cryo for yourself!